AC compressor working principle might sound like jargon, but it’s not as complicated as it seems. This article will dig into what makes this component tick.

Table of Contents

Understanding the Basics of an Air Conditioning System

If we’re going to understand the working principle of an AC compressor, we first need to grasp the basics of an air conditioning system as a whole.

Components of an Air Conditioning System

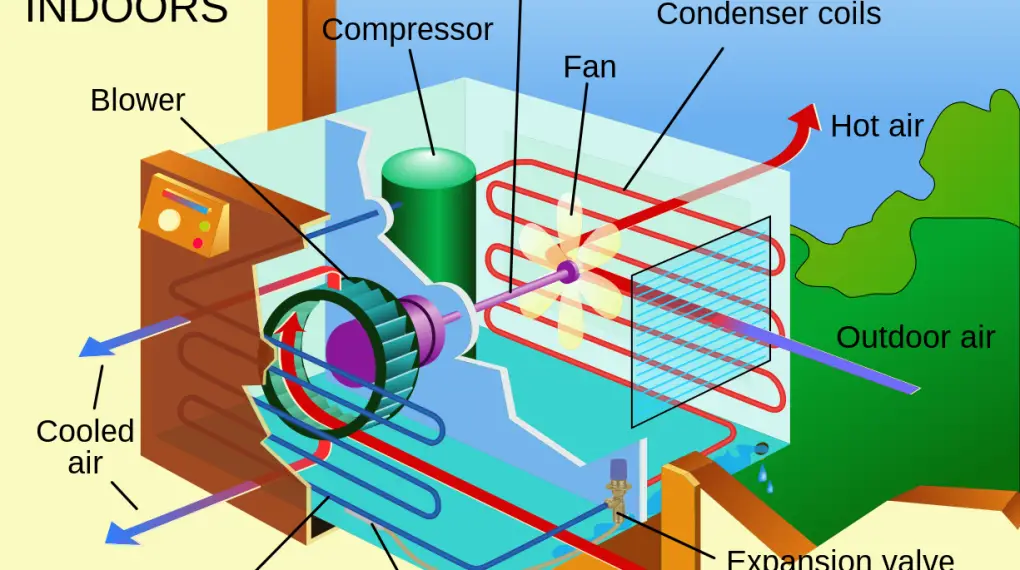

An air conditioning system is like an orchestra with several components playing together to cool your space. You’ve got the condenser, evaporator, expansion valve, and of course, our star player, the AC compressor. Each part does a different job, but they’re all tied together by the rhythm of the refrigerant flow.

Role of the AC Compressor

So, where does our hero fit in the grand scheme of things? Well, the AC compressor starts the refrigeration cycle. It takes in refrigerant gas from the evaporator, compresses it to a higher temperature and pressure, and sends it to the condenser. That’s a heck of a job, isn’t it?

Delving Deeper into the AC Compressor Working Principle

So, what’s the magic behind the AC compressor? Let’s find out.

Step-by-step Analysis of the AC Compressor Working Principle

Suction Stage

Picture the AC compressor like a big straw, sucking in refrigerant gas from the evaporator. This is the first stage, folks. The low-pressure gas enters the compressor ready to start a transformative journey.

Compression Stage

Ever squeezed a balloon full of air? That’s what the compressor does to the refrigerant gas. It compresses it, which increases both its temperature and pressure. It’s all physics, folks.

Discharge Stage

The high-pressure, high-temperature gas then leaves the compressor and heads over to the condenser. Imagine this like a relay race, and the compressor just handed off the baton.

How the Compressor’s Function Affects Cooling

Imagine trying to cool your house with just a fan, sounds inefficient, right? That’s why we need the compressor. The compressor’s magic trick of turning low-pressure gas into high-pressure gas is what kickstarts the whole cooling process.

Check out these other related articles…

How to Replace AC Compressor Clutch: A Comprehensive Guide

AC Compressor Clutch Problems [Diagnosis & Repair]

RV AC Compressor Not Turning On [Diagnosis & Fixes]

RV AC Compressor Not Turning Off: Causes & Solutions

AC Compressor Connection: All You Need to Know

Different Types of AC Compressors and Their Working Principles

Did you know that not all AC compressors are created equal? In fact, there are several types of AC compressors, each with their unique working principles.

Reciprocating Compressors

Reciprocating compressors work a bit like a car engine, using pistons to compress the refrigerant gas. Think of them as the old reliable of AC compressors. They’ve been around for a while, and they’re not going anywhere anytime soon.

Scroll Compressors

Ever twisted a paperclip into a spiral? That’s pretty much the shape of the components inside a scroll compressor. It uses two spiral-shaped pieces to compress the refrigerant. One piece remains stationary while the other orbits around it, compressing the refrigerant gas in the process. The result? A reliable and efficient operation that’s gaining popularity in residential AC systems.

Rotary Compressors

Imagine a hamster running on a wheel. That’s kind of how rotary compressors work. A rotating component (the hamster) compresses the refrigerant against the sides of a cylindrical housing (the wheel). It’s a smooth and quiet operation, making rotary compressors popular for small spaces where noise could be an issue.

Screw Compressors

Picture a couple of screws turning together, trapping and compressing gas between them. That’s the essence of a screw compressor. These big guys are typically found in industrial applications due to their high capacity and efficiency.